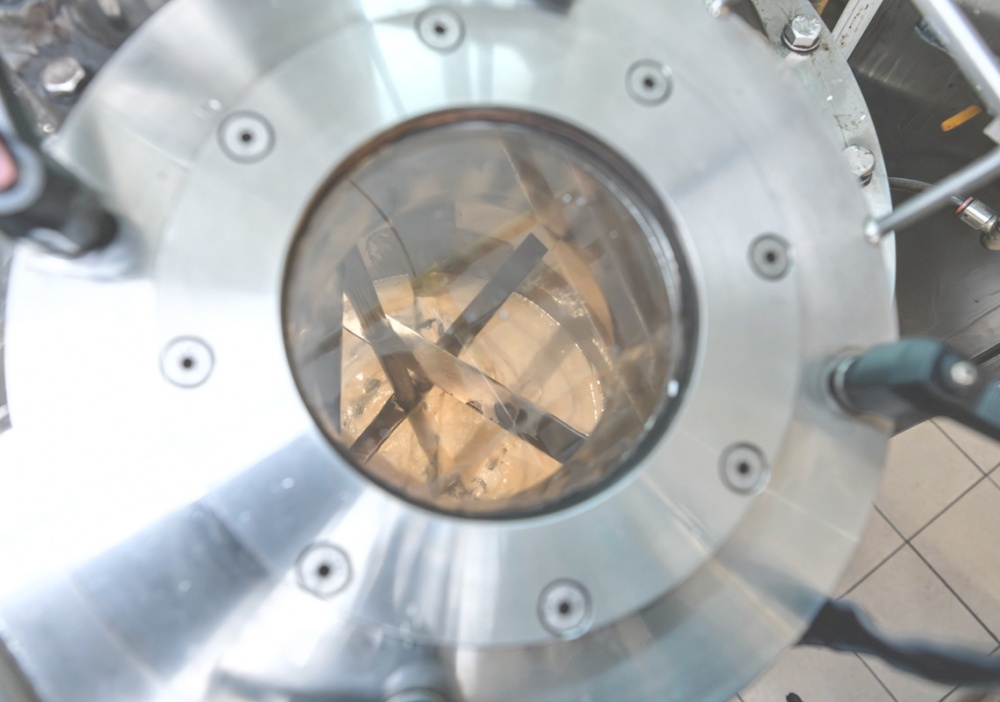

The daily production of 4,000 Kg is carried out in vacuum turbo-emulsifiers of various capacities.

The versatility of the production lines allows us to produce both small batches of 250 pieces and large quantities of semi-finished or finished product, which we deliver ready to market.

Due to the versatility of production, we offer the best price/quality ratio on the market for 100 Kg batches packaged in 60ml or 100ml tubes, with an additional discount for larger quantities, while having the possibility of producing small batches of up to 25 or 50 Kg with a physiological increase in costs.

Request a Quote

At every stage of production and packaging, the quality and characteristics of the colour cream are preserved from contact with air by being kept in a controlled and protected atmosphere.

All stages of the production process follow pre-established procedures, whereby the temperature, mixing speed and cooling of each individual mixer are constantly monitored.

In accordance with current regulations, samples for each production batch are stored for 10 years from the date of packaging, available for subsequent checks.

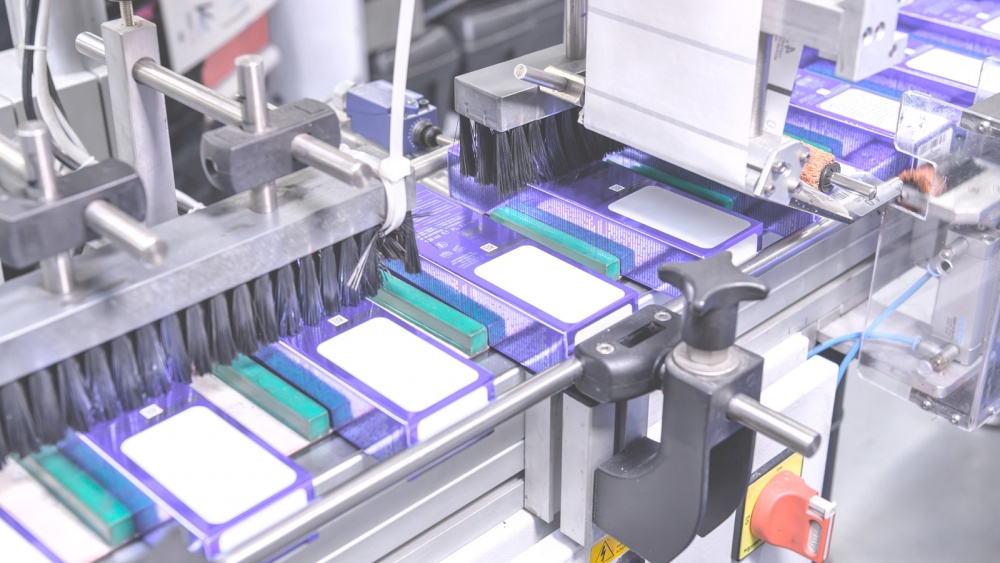

Packaging is carried out with automatic lines, starting with the filling of the individual 60ml or 100ml tubes coded with laser engraving, to the subsequent positioning in the cartons, continuing with labelling and then reaching the final stage of 3-piece blistering with boxing in 36-piece ink-jet-coded boxes.

Once the packaging is finished, the pallet is taken to the logistics area for shipment with storage awaiting collection.

Watch in 2 minutes how HG HairGloss helps you create a unique and exclusive hair colour cream line with your own brand.

YouTube

Daily capacity of our production lines.

Perfectly balanced formulas.

Loyal customers in a lasting partnership.

Global markets to which our customers export.

Prefer a more immediate response? Use WhatsApp to access the chat with Customer Support.

Alternatively, please fill the Form to be contacted within 48 hours.